PDF version of the paper (0.4 MB).

2.1. Classification of methods

2.2. Fuel rate calculation methods used in Russia

2.2.1. “Physical” method

2.2.2. Exergy method

2.2.3. Proportional distribution method by ORGRES

2.2.4. Work method (Russian name is “method on under-produced electricity”)

2.2.5. Steam parameters consideration method

2.3. Cost allocation methods used in countries with developed electricity and heat markets

2.3.1. Exergy method

2.3.2. Work method

2.3.3. Energy method

2.3.4. Method of an alternative way of heat supply

2.3.5. Method of an alternative way of electricity supply

2.3.6. Benefit distribution method

2.3.7. Benefit and risk-sharing method

2.1. Classification of methods

The cost allocation methods are usually divided into two groups [1], [2], [3], [6]:

- thermodynamic

- economic.

The purpose of thermodynamic methods is to determine the technical efficiency of the CHP plant operation modes. The methods consider the thermodynamic details of the combined heat and power production technology [4]. These methods include:

- “physical” (the other names in Russian literature are heat, balance, and enthalpy) (section 2.2.1)

- exergy (sections 2.2.2, 2.3.1)

- proportional distribution by ORGRES (section 2.2.3)

- work (sections 2.2.4, 2.3.2)

- steam parameters consideration (section 2.2.5).

The purpose of economic cost allocation methods is to increase the CHP plant product competitiveness in the electricity and heat markets [2], [3], [6]. The CHP plant competitive ability in the markets is determined by the cost of its products: the price of the product to be supplied should be lower than the marginal market price [5]. As mentioned above, the cost value of the CHP plant product is an economic indicator based on the fuel rate value. The list of these methods includes:

- energy (section 2.3.3)

- an alternative way of heat supply (section 2.3.4)

- an alternative way of electricity supply (section 2.3.5)

- benefit distribution (section 2.3.6)

- benefit and risk-sharing (section 2.3.7).

2.2. Fuel rate calculation methods used in Russia

Despite the Russian wholesale electricity market development, the problem of fuel rate calculation is solved exclusively by thermodynamic methods [3], [4], [9], [11]. According to the market rules, the result of the fuel rate calculation is used to determine the day-ahead and intraday bidding price for one MWh of electricity supply [5]. In the case of a “weird” participant bidding price, the exchange is allowed to demand the details of fuel rate calculation to evaluate the participant price. Speaking about Russian methods, I use the fuel rate term.

2.2.1. “Physical” method

The “physical” method for fuel rate calculation for CHP plant production of electricity, industrial steam, and heat was the official one in Russia until 1996 [3]. Since 2013, this method has become official in Russia again [9]. Sometimes, this method is called the heat [9], balance [4], or enthalpy [8] method. Ironically, the method doesn’t reflect the physics of the combined heat and power production process, thus, I put its name in the quotes.

The “physical” method requires an additional input value: the total high-pressure steam consumption \[Q_0\], MWh.

According to the “physical” method, the fuel rate calculation is carried out in two steps.

1) Distribute the total consumption of equivalent fuel between different CHP plant products

The consumption of equivalent fuel for electricity generation \[Q_E\] is given by the expression:

\[B_E = \frac {Q_E}{Q_0} \cdot B \]

where \[Q_E\] is the high-pressure steam consumption for electricity generation, MWh. The value of \[Q_E\] is calculated from the steam balance:

\[ Q_0 = Q_E + Q_M + Q_L \hspace{1cm} (5)\]

The consumption of equivalent fuel for industrial steam and heat production are given by the corresponding formulas:

\[ B_M = \frac{Q_M}{Q_0} \cdot B \]

\[ B_L = \frac{Q_L}{Q_0} \cdot B \]

2) Calculate fuel rate

The fuel rates \[b_E, b_M, b_L\] are calculated using equations (1) – (3). In case of gross generation fuel rates, auxiliary services \[E^{AUX}, Q_M^{AUX}, Q_L^{AUX}\] should be set to zero MWh; for the net generation fuel rates the auxiliary services values should be defined for a certain CHP plant operation mode. In the xlsx-appendix, \[E^{AUX} = 3 MWh\] and \[Q_M^{AUX} = Q_L^{AUX} = 0 MWh \]. This paragraph is being applied for all final steps of the following methods.

2.2.2. Exergy method

The exergy method is considered the most “fair” and correct thermodynamic method [2], [4], [6]. The concept of exergy is to evaluate the quality of different forms of energy [13]. The method is adopted in countries with developed electricity markets to assess the technical efficiency of CHP plants' operation modes [2], [6] (section 2.3.1).

The method requires additional input parameters describing the CHP plant operation mode:

- enthalpy and entropy of various types of steam and their condensate

- outside temperature.

The exergy method for each CHP plant product consists of three steps.

1) Find the total energy of the CHP plant products

Total CHP plant operation mode exergy \[E_{TOTAL}\]5 in MWh is calculated using the formula:

5Be careful, I use E for the CHP plant electricity production; and here, \[E_E\] means exergy for electricity product and total exergy is denoted with \[E_{TOTAL}\]. You may ask: why do I do this? Simply because in English language papers, the most often used notation for electricity – \[E\], for exergy – \[E \] either.

\[ E_{TOTAL} = E_E + E_M + E_L \]

The values of exergies \[E_E, E_M, E_L \], MWh are calculated using the following expressions:

- Electricity exergy

\[ E_E = E\]

- Industrial steam exergy

\[ E_M = Q_M \cdot \left ( 1 - \frac{T_{env}}{T_M} \right ) \]

- Heat exergy

\[ E_L = Q_L \cdot \left ( 1 - \frac{T_{env}}{T_L} \right ) \]

Here, \[T_{env}\], К, is the outside temperature; \[T_M, T_L\], К, are average industrial steam temperature \[Q_M\] and average low-pressure steam temperature required for heat \[Q_L\] production.

The value of \[T_M\] is defined by the following formula:

\[ T_M = \frac{H_M^c - H_M}{S_M^c-S_M} \]

where \[H_M, S_M\] are enthalpy, kJ/kg, and entropy, kJ/kg·K, of industrial steam; \[H_M^c, S_M^c\] are enthalpy and entropy of industrial steam condensate correspondingly.

Analogously, \[T_L\] value is derived from the expression:

\[ T_L = \frac{H_L^c - H_L}{S_L^c-S_L} \]

where \[H_L, S_L\] are enthalpy and entropy of low-pressure steam which is required for heat production \[Q_L\];\[H_L^c, S_L^c\] are enthalpy and entropy of low-pressure steam condensate.

2) Distribute of the total exergy by CHP plant products

The equivalent fuel consumption for electricity production is determined by the expression:

\[ B_E = \frac{E_E}{E_{TOTAL}} \cdot B \]

Correspondingly, the equivalent fuel consumption for the industrial steam and heat production equal:

\[ B_M = \frac{E_M}{E_{TOTAL}} \cdot B \]

\[ B_L = \frac{E_L}{E_{TOTAL}} \cdot B \]

3) Calculate fuel rate

The fuel rates \[b_E, b_M, b_L\] are calculated using equations (1) – (3).

2.2.3. Proportional distribution method by ORGRES

This method used to be an official method for preparing reports on the CHP plants' technical efficiency within the period 1996 – 2013 [4], [14].

This method requires the following additional input data:

- the total consumption of high-pressure steam

- enthalpies of various types of steam

- enthalpy of the high-pressure steam condensate

- factor6 for regenerative heating of feed water.

6This coefficient notation is the only difference from γ, for details see the xlsx-appendix.

The method consists of four steps.

1) Find steam coefficients

The industrial steam coefficient is calculated using the formula:

\[ \gamma_M = \frac{H_M - H^c_0}{H_0 - H^c_0} \cdot \left ( 1 + k \cdot \left ( \frac{H_0 - H_M}{H_0 - H_0^c} \right ) \right ) \hspace{1cm} (6)\]

where \[H_0, H_0^c\] are enthalpies and entropies of high-pressure steam and its condensate, kJ/kg. The value of factor \[k\] depends on CHP plant equipment nomenclature and is provided by ORGRES [14].

Analogously, the value coefficient of low-pressure steam is determined as:

\[ \gamma_L = \frac{H_L - H^c_0}{H_0 - H^c_0} \cdot \left ( 1 + k \cdot \left ( \frac{H_0 - H_L}{H_0 - H_0^c} \right ) \right ) \hspace{1cm} (7)\]

2) Calculate electricity fuel rate

The fuel rate for total electricity production E is calculated by the formula:

\[ B_E = B \cdot \gamma_{dE} \hspace{1cm} (8)\]

where \[\gamma_{dE}\] is a special coefficient for electricity production. This coefficient is derived using the expression:

\[ \gamma_{dE} = \frac{Q_E + \Delta Q_E}{Q_E + \Delta Q_E + Q_M + Q_L} \]

Here, \[Q_E\] is the high-pressure steam consumption for electricity production that was obtained in the “physical” method (5); \[\Delta Q_E\] is additional high-pressure steam consumption for electricity production, MWh equals:

\[ \Delta Q_E = Q_M (1 - \gamma_M) + Q_L (1 - \gamma_L)\]

At the end of this step, the electricity fuel rate \[b_E\] is calculated with equation (1).

3) Calculate industrial steam fuel rate

The industrial steam fuel rate is determined by the statement:

\[ b_M^{TOTAL} = b_{ML} - \Delta b_M \]

where \[b_{ML}\] is the total fuel rate for industrial steam and heat production combined, tef/MWh; \[\Delta b_M\] is a reduction of industrial steam fuel rate, tef/MWh.

The total fuel rate for industrial steam and heat production combined is calculated as follows:

\[ b_{ML} = \frac {B_{ML}}{Q_M + Q_L} \]

Here, \[B_{ML}\] is the total fuel consumption for industrial steam and heat production combined determined as the difference:

\[ B_{ML} = B - B_E \hspace{1cm} (9)\]

The value of \[B_E\] is calculated on the previous step (8).

The reduction for industrial steam fuel rate is obtained with:

\[ \Delta b_M = \Delta b_{ML} \cdot \frac {1 - \gamma_M}{1 - \gamma_{ML}} \]

Here, \[\Delta b_{ML}\] is the total reduction of the total fuel rate for industrial steam and heat production combined, tef/MWh; \[\gamma_{ML}\] is an average of the steam coefficient for industrial steam and low-pressure steam. The value \[\Delta b_{ML}\] is calculated by the formula:

\[ \Delta b_{ML} = b_{ML} \cdot \left ( \frac {Q_E + \Delta Q_E + Q_M + Q_L}{Q_E + Q_M + Q_L} - 1 \right ) \hspace{1cm} (10)\]

The value \[\gamma_{ML}\] id determined by the statement:

\[ \gamma_{ML} = \frac{Q_M \cdot \gamma_M + Q_L \cdot \gamma_L}{Q_M + Q_L} \hspace{1cm} (11)\]

The industrial steam net production fuel rate is calculated as follows:

\[ b_M = b_m^{TOTAL} \cdot \frac {Q_M}{Q_M - Q_M^{AUX}}\]

In case \[Q_M^{AUX} = 0\], the fuel rate for both total and net production are equal to \[b_M^{TOTAL}\].

4) Calculate heat fuel rate

Analogously with industrial steam, the total heat production fuel rate is defined with the expression:

\[ b_L^{TOTAL} = b_{ML} - \Delta b_L \]

Here, \[\Delta b_L\] is the reduction of industrial steam and heat fuel rate combined, tef/MWh, it's equal to:

\[ \Delta b_L = \Delta b_{ML} \cdot \frac {1 - \gamma_L}{1-\gamma_{ML}} \]

Values \[\Delta b_{ML}, \gamma_{ML}\], were calculated with the formulas (10) and (11) above.

Thus, the net heat production fuel rate equals:

\[ b_L = b_L^{TOTAL} \cdot \frac {Q_L}{Q_L - Q_L^{AUX}}\]

2.2.4. Work method (Russian name is “method on under-produced electricity”)

This method is based on taking into account the reduction of electricity production due to applying high-pressure steam for industrial steam and heat production [2], [4]. The method is applied both in Russia and in other countries with developed electricity and heat markets.

The method requires the input data about additional CHP plant operation modes as presented in Table 1.

| Current mode | Mode 1 | Mode 2 | Mode 3 |

|---|---|---|---|

| Q0 | Q10 = Q0 | Q20 = Q0 | Q30 = Q0 |

| QM | Q1M = 0 | Q2M = QM | Q3M = 0 |

| QL | Q1L = QL | Q2L = 0 | Q3L = 0 |

| E | E1 | E2 | E3 |

Electricity productions \[E^1, E^2, E^3\] are determined in accordance with turbine characteristic curves [15] for the quantities of high-pressure steam, industrial steam, and heat production indicated in the table.

The method consists of the following three steps.

1) Calculate electricity fuel rate

Fuel consumption for electricity production is defined with the expression:

\[ B_E = B \cdot \frac{E}{E^3}\]

Then, the electricity fuel rate is calculated with formula (1).

2) Calculate industrial steam fuel rate

The fuel consumption for industrial steam production is calculated as follows:

\[ B_M = \frac {B_{ML}}{1 + \frac{1}{\gamma_{ML}}} \]

In this method, coefficient \[\gamma_{ML}\] defines the industrial steam to heat ratio. The value of the ratio is defined by the expression:

\[ \gamma_{ML} = \frac {E^3 - E^1}{E^3 - E^2}\]

The value of \[B_{ML}\] is calculated with formula (9); the industrial steam fuel rate with formula (2).

3) Calculate heat fuel rate

The fuel consumption for heat production comes from:

\[ B_L = \frac{B_M}{\gamma_{ML}}\]

The value of \[\gamma_{ML}\] is calculated in the previous step.

The heat fuel rate is calculated in accordance with formula (3).

2.2.5. Steam parameters consideration method

This method is based on taking into account the quality of different kinds of steam using the steam quality coefficients calculated in accordance with the proportional distribution method by ORGRES (section 2.2.3).

Additional input data:

- total high-pressure steam consumption

- the enthalpies of the steams

- the enthalpy of high-pressure steam condensate

- factor k for regenerative heating of feed water.

The method consists of three steps.

1) Calculate steam coefficients

Here, the steam coefficients \[\gamma_M, \gamma_L\] are calculated by the formulas (6), and (7) respectively.

2) Calculate electricity fuel rate

The fuel consumption for electricity production is defined with the expression:

\[ B_E = B \cdot \gamma_{B_E} \hspace{1cm} (12)\]

where \[\gamma_{B_E}\] is a new coefficient which is obtained as follows:

\[ \gamma_{B_E} = \frac {Q_0 - (Q_M \gamma_M + Q_L \gamma_L)}{Q_0} \]

The electricity fuel rate is calculated in accordance with formula (1).

3) Calculate industrial steam fuel rate

Analogously to (12), the fuel consumption for industrial steam production equals:

\[ B_M = B \cdot \gamma_{B_M} \]

where \[\gamma_{B_M}\] is another additional coefficient determined as follows:

\[ \gamma_{B_M} = \frac {Q_M \gamma_M}{Q_M \gamma_M + Q_L \gamma_L} \]

The industrial steam fuel rate is calculated in accordance with formula (2).

4) Calculate heat fuel rate

As previously, the fuel consumption for heat production equals:

\[ B_L = B \cdot \gamma_{B_L} \]

Where coefficient \[\gamma_{B_L}\] is calculated by the expression:

\[ \gamma_{B_L} = \frac {Q_L \gamma_L}{Q_M \gamma_M + Q_L \gamma_L} \]

The heat fuel rate is defined by formula (3).

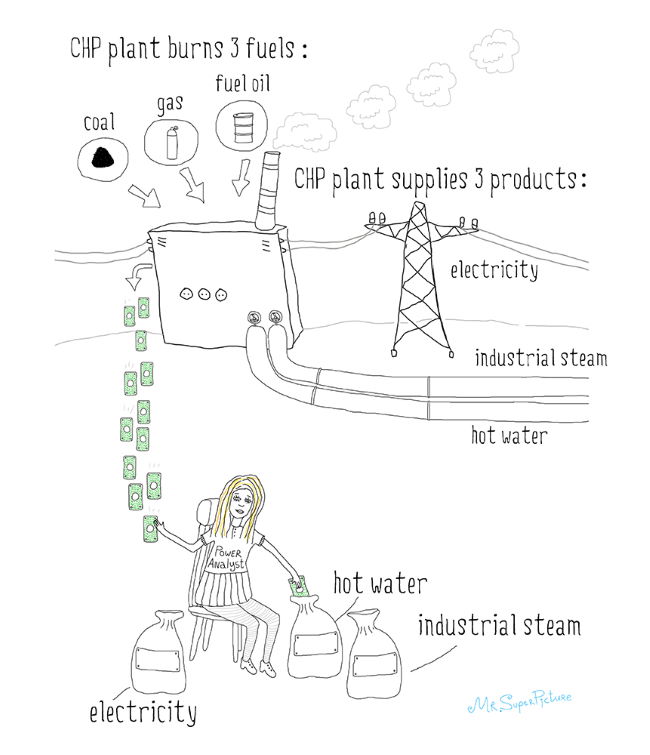

2.3. Cost allocation methods used in countries with developed electricity and heat markets

In countries with developed electricity and heat markets, the cost allocation problems are discussed [1], [2], [6]. The problem is solved in order is to increase the competitiveness of CHP plants in the electricity and heat markets. The result of the calculation is the production cost per unit for CHP plant products (electricity, industrial steam, heat).

In this paper, Western methods for estimating the production cost per unit for a CHP plant are slightly adapted and split into two steps:

- fuel rate calculation, tef/MWh

- product cost calculation based on obtained fuel rate and equivalent fuel cost, EUR/MWh (see details below).

This approach allows us to compare fuel rate values for Russian and Western methods combined. Thus, the following agreements are adopted.

- Total fuel cost:

\[ C_B = B \cdot Z_B\]

where \[C_B\] is fuel cost, EUR; \[Z_B\] is the equivalent fuel price, EUR/tef.

- Product costs:

\[ Z_E = b_E \cdot Z_B \hspace{1cm} (13)\]

\[ Z_M = b_M \cdot Z_B \hspace{1cm} (14)\]

\[ Z_L = b_L \cdot Z_B \hspace{1cm} (15)\]

Here, \[Z_E, Z_M, Z_L \] are CHP plant product costs, EUR/MWh. In Russia, these values are commonly referred to as product fuel cost [5].

Since the costs of industrial steam production are not accounted for in some of the works [2], [6], the methods considered in these works have been supplemented based on the following considerations:

- An alternative to the combined production of industrial steam is the steam generated by a reduction-cooling unit

- Industrial steam is supplied at a contract price that is not subjected to market risks.

2.3.1. Exergy method

The exergy method used in countries with developed electricity and heat markets is identical to the exergy method used in Russia (section 2.2.2). The method is mainly applied to assess the technical efficiency of a CHP plant operation.

2.3.2. Work method

The work method is identical to the method of under-produced electricity used in Russia (section 2.2.4). The method is mainly applied to assess the technical efficiency of a CHP plant's operation.

2.3.3. Energy method

According to this method, the cost allocation problem is solved in the following two steps [2].

1) Allocate total fuel consumption by product

The fuel consumption for electricity production equals:

\[ B_E = B \cdot \frac {E}{E + Q_M + Q_L} \]

Similarly, the fuel consumption for industrial steam and heat productions are calculated as follows:

\[ B_M = B \cdot \frac {Q_M}{E + Q_M + Q_L} \]

\[ B_L = B \cdot \frac {Q_L}{E + Q_M + Q_L} \]

2) Calculate fuel rates and product costs

The specific fuel rates are calculated based on formulas (1) – (3); product costs on formulas (13) – (15).

2.3.4. Method of an alternative way of heat supply

This method assumes that an alternative to the combined heat production is the production of heat \[Q_L\] by a hot-water boiler and industrial steam \[Q_M\] by a reduction-cooling unit [1], [2].

Additional input data:

- hot-water boiler efficiency

- steam boiler efficiency

- reduction-cooling unit efficiency is taken as 100%.

The cost allocation problem is solved in two steps.

1) Allocate total fuel consumption by product

The consumption of equivalent fuel for alternative heat production is given by the statement:

\[ B_L = B_L^a = \gamma_{tef} \cdot \frac {Q_L}{\eta_{WB}} \hspace{1cm} (16)\]

where \[\gamma_{tef}\] is a constant equal to 0,123 tef/MWh.

The fuel consumption for industrial steam production is calculated analogously:

\[ B_M = B_M^a = \gamma_{tef} \cdot \frac {Q_M}{\eta_{SB}} \hspace{1cm} (17)\]

Here, \[\eta_{WB}\] is a water-boiler efficiency, \[\eta_{SB}\] is a steam boiler efficiency.

Note, that a water-boiler efficiency is not a technical characteristic of a certain boiler but a variable that may take a value in the range from 92% to 112%. The variable allows flexibility in the product's cost allocation depending on the market price expectations. Recommendations for setting this value are given in the work [2].

The fuel consumption for electricity production is given by the expression:

\[ B_E = B - (B_M + B_L) \]

2) Calculate fuel rates and product costs

The specific fuel rates are calculated based on formulas (1) – (3); product costs on formulas (13) – (15).

2.3.5. Method of an alternative way of electricity supply

This method is based on the assumption that the condensational electricity supply is an alternative to the electricity co-generation [1], [2]. A CHP plant condensational operation mode is the mode when a CHP plant supplies electricity only, output of the other products are equal to 0.

An additional input value is the consumption of high-pressure steam \[Q_0^c\] for the power production \[E\] in condensational operation mode. The value of \[Q_0^c\] is determined in accordance with the turbine characteristic curves [15].

The method consists of two steps.

1) Allocate total fuel consumption by product

The fuel consumption for electricity production equals:

\[ B_E = B_E^a = B \cdot \frac {Q_0^c}{Q_0} \hspace{1cm} (18)\]

Analogously, fuel consumption for industrial steam and heat production are derived according to:

\[ B_M = (B - B_E) \cdot \frac {Q_M}{Q_M + Q_L}\]

\[ B_L = (B - B_E) \cdot \frac {Q_L}{Q_M + Q_L}\]

2) Calculate fuel rates and product costs

The specific fuel rates are calculated based on formulas (1) – (3); product costs on formulas (13) – (15).

2.3.6. Benefit distribution method

This method is based on the allocation of the consumption of equivalent fuel in proportion to the consumption of alternative production of all CHP plant products. The considered method is a combination of the method of alternative heat supply (section 2.3.4) and the method of alternative electricity supply (section 2.3.5) [2].

The additional input data are:

- hot-water boiler efficiency

- steam boiler efficiency

- reduction-cooling unit efficiency is taken as 100%

- the consumption of high-pressure steam \[Q_0^c\] for the power production \[E\] in condensational mode.

The method consists of two steps.

1) Allocate total fuel consumption by product

The specific fuel consumption for the production of electricity, industrial steam, and heat are calculated by formulas (18), (17), and (16) respectively.

Note that, in this method, the real technical water-boiler efficiency is used in contrast to the method of alternative heat supply, where this value is a variable [2], [6].

Total alternative fuel consumption for three product combined equals:

\[ B^a = B_E^a + B_M^a + B_L^a \]

The fuel consumption for electricity production is calculated by the expression:

\[ B_E = B \cdot \frac {B_E^a}{B^a}\]

Analogously, fuel consumption for industrial steam and heat production are derived as follows:

\[ B_M = B \cdot \frac {B_M^a}{B^a}\]

\[ B_L = B \cdot \frac {B_L^a}{B^a}\]

2) Calculate fuel rates and product costs

The specific fuel rates are calculated based on formulas (1) – (3); product costs on formulas (13) – (15).

2.3.7. Benefit and risk-sharing method

This method allows taking into account the risk of the market electricity price changes [2]. For this method, an additional input value is the expected change in the market electricity price \[ r \in [-1;1]\] that reflects the market expectation. The value of r is positive when an increase in electricity prices is expected, and negative otherwise.

In this work, the risk r is applied at fuel rate calculation. Remember, that fuel rates are connected to product costs by expressions (13) – (15).

According to this method, the problem is solved in the following two steps.

1) Calculate fuel rates and product costs

The calculation is done in accordance with the alternative heat supply method (section 2.3.4).

2) Adjust fuel rates

To increase competitiveness in the electricity and heat markets simultaneously, the consumption of equivalent fuel is redistributed between these two market products. The main product is electricity, as its market price is the most volatile. The value of r is used to re-evaluate the fuel rate as follows:

\[ b_E^{market} = b_E (1 + r) \]

To maintain the fuel balance (4) the heat fuel rate is adjusted the following way:

\[ b_L^{market} = \frac {(B - B_M) - b_E^{market} \cdot (E - E^{AUX})}{Q_L - Q_L^{AUX}} \]

Therefore, with an increase in the electricity fuel rate, the heat fuel rate is reduced, and vice versa. The values of \[b_E^{market}, b_L^{market}\] are the basis for market bidding. The value of \[b_M\] remains constant.