PDF version of the paper (0.4 MB).

3.1. A steam turbine linear characteristic curve

3.2. Method description

3.3. Example

3.1. A steam turbine linear characteristic curve

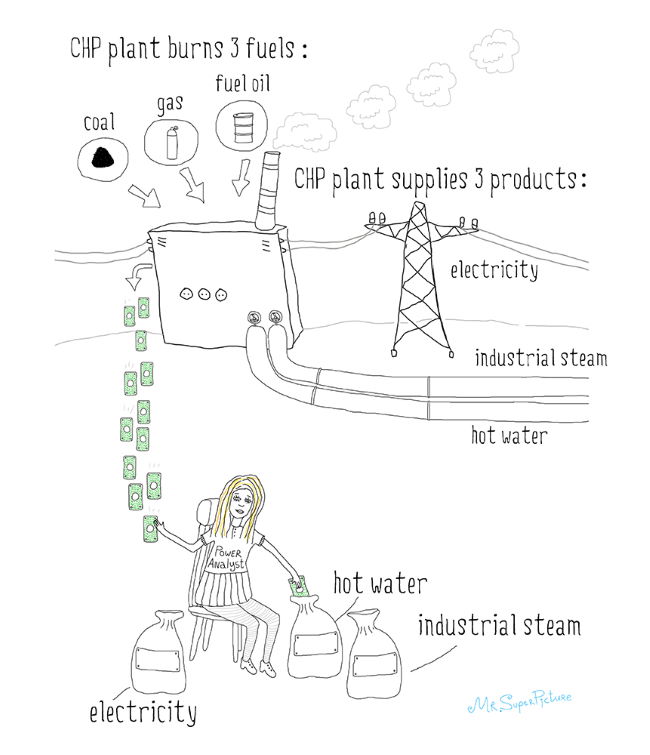

A linear characteristic curve has been developed for both gas and steam turbines during the CHP plant optimization project. The details of the project are discussed in my previous paper [16]. Currently, it's in Russian, but I've scheduled its translation to English in 2021. In the present paper, a steam turbine is considered only.

A linear characteristic curve for steam turbine g looks as follows [16]:

\[ Q_0^g = \alpha_E^g E^g + \alpha_M^g Q_M^g + \alpha_L^g Q_L^g + \alpha_0^g + \epsilon^g \hspace{1cm} (19)\]

where \[g \in [1:G]\] is a steam turbine number; \[\alpha_i^g\] are linear coefficients; \[\epsilon^g\] is the error of linearization. The algorithm to get a linear characteristic curve and \[\alpha_i^g\] values for both steam and gas turbines is developed in work [16]. An average mean absolute percentage error of linearization of various types of turbines comprises 0.6%. See error details in the paper [16].

The total consumption of high-pressure steam by the turbine g is split into three parts:

\[ Q_0^g = Q_0^g(E) + Q_0^g(Q_M) + Q_0^g(Q_L) \hspace{1cm} (20)\]

Here, \[Q_0^g(E), Q_0^g(Q_M), Q_0^g(Q_L)\] are consumption of high-pressure steam for production electricity, industrial steam, and heat, respectively, MWh.

Define the consumption of high-pressure steam for the production of electricity based on a linear characteristic curve (19):

\[ Q_0^g = \alpha_E^g E^g + \alpha_0^g\]

Value \[\alpha_0^g\] is called idle consumption, i. e. consumption of high-pressure steam when the turbine doesn't generate any output. This value is allocated for electricity generation [17].

Consumption of high-pressure steam for industrial steam and heat production is determined by the following statements:

\[ Q_0^g(Q_M^g) = \alpha_M^g Q_M^g \]

\[ Q_0^g(Q_L^g) = \alpha_L^g Q_L^g \]

3.2. Method description

This method is a thermodynamic method for the fuel rate calculation. The method is based on the high-pressure steam equation (20).

The additional input data are the coefficients of the linear characteristic curve for the steam turbine of a CHP plant [16].

According to this method, the problem is solved in the following three steps.

1) Find high-pressure steam consumption for CHP plant products

For a set of CHP plant steam turbines, the consumption of high-pressure steam for electricity generation is:

\[ Q_0(E) = \sum_{g=1}^{G} Q_0^g(E^g) = \sum_{g=1}^{G} \left ( \alpha_E^g E^g + \alpha_0^g \right ) \]

where Q0(E) is the total high-pressure steam consumption for CHP plant electricity production E. Note, that a similar technique has been developed for gas turbines7.

7 If you're interested in equations for the gas turbine, please, contact me.

In the same style, I define equations for total high-pressure steam consumption for industrial steam and heat production:

\[ Q_0(Q_M) = \sum_{g=1}^{G} Q_0^g(Q_M^g) = \sum_{g=1}^{G} \alpha_M^g Q_M^g \]

\[ Q_0(Q_L) = \sum_{g=1}^{G} Q_0^g(Q_L^g) = \sum_{g=1}^{G} \alpha_L^g Q_L^g \]

2) Allocate total fuel consumption by CHP plant products

The fuel consumption for electricity production equals:

\[ B_E = B \cdot \frac {Q_0(E)}{Q_0} \]

Analogously, the fuel consumption for industrial steam and heat production is calculated according to:

\[ B_M = B \cdot \frac {Q_0(Q_M)}{Q_0} \]

\[ B_L = B \cdot \frac {Q_0(Q_L)}{Q_0} \]

3) Calculate fuel rates and product costs

The specific fuel rates are calculated based on formulas (1) – (3); product costs on formulas (13) – (15).

3.3. Example

For the CHP plant under consideration in xlsx-appendix, the co-generation is carried out by a steam turbine ST-135. A diagram of the CHP plant operation mode is given in [4].

Input data:

- Electricity production \[E = 80 \] MWh, electricity auxiliary service \[E^{AUX} = 3\] MWh

- Industrial steam production \[Q_m = 144.2\] MWh, industrial steam auxiliary service \[Q_m^{AUX} = 0\] MWh

- Heat production \[Q_L = 93\] MWh, heat auxiliary service \[Q_L^{AUX} = 0\] MWh

- Total fuel consumption \[B = 48.4\] tef

- Linear coefficients for ST-135 \[\alpha_E = 1.8492, \alpha_M = 0.7146, \alpha_L = 0.2820, \alpha_0 = 95.6873\]8.

8 The calculation of coefficients is carried out in the paper xlsx-appendix, sheet “ST-135 linear charact. Curve.”

1) Find high-pressure steam consumption for CHP plant products

High-pressure steam consumption for electricity production equals, MWh:

\[ Q_0(E) = \alpha_E E + \alpha_0 = 1.8492 \cdot 80 + 95.6873 = 243.6 \]

High-pressure steam consumption for industrial steam and heat production, MWh:

\[ Q_0(Q_M) = \alpha_M Q_M = 0.7146 \cdot 144.2 = 103.1 \]

\[ Q_0(Q_L) = \alpha_L Q_L = 0.2820 \cdot 93 = 26.2 \]

Total high-pressure steam consumption is the sum of the three parts above, MWh:

\[ Q_0 = Q_0(E) + Q_0(Q_M) + Q_0(Q_L) = 243.6 + 103.1 + 26.2 = 372.9 \]

2) Allocate total fuel consumption by CHP plant products

The fuel consumption for electricity production is, tef:

\[ B_E = B \cdot \frac {Q_0(E)}{Q_0} = 48.4 \cdot \frac{243.6}{372.9} = 31.6 \]

Analogously, the fuel consumption for industrial steam and heat production is, tef:

\[ B_M = B \cdot \frac {Q_0(Q_M)}{Q_0} = 48.4 \cdot \frac{103.1}{372.9} = 13.4 \]

\[ B_L = B \cdot \frac {Q_0(Q_L)}{Q_0} = 48.4 \cdot \frac{26.2}{372.9} = 3.4 \]

3) Calculate fuel rates and product costs

Fuel rates for CHP plant products net supply are, tef/MWh:

\[ b_E = \frac{B_E}{E-E^{AUX}} = \frac{31.6}{80-3} = 0.411 \]

\[ b_M = \frac{B_M}{Q_M-Q_M^{AUX}} = \frac{13.4}{144.2-0} = 0.093 \]

\[ b_L = \frac{B_L}{Q_L-Q_L^{AUX}} = \frac{3.4}{93-0} = 0.037 \]

And product costs are, EUR/MWh:

\[ Z_E = b_E Z_B = 0.411 \cdot 100 = 41.1\]

\[ Z_M = b_M Z_B = 0.093 \cdot 100 = 9.3\]

\[ Z_L = b_L Z_B = 0.037 \cdot 100 = 3.7 \]

The additional calculation is shown in the xlsx-appendix.